This is is a short demonstration of a co-simulation between Siemens PLCSIM Advanced and C#. The goal is simple : have the ability to conditionally change inputs. We’ll do a proof of concept with a small example for a safety relay monitored by a feedback.

For Siemens PLC simulation with virtual commissioning we’ll use PLCSIM Advanced and C# co-simulation.

Configuration

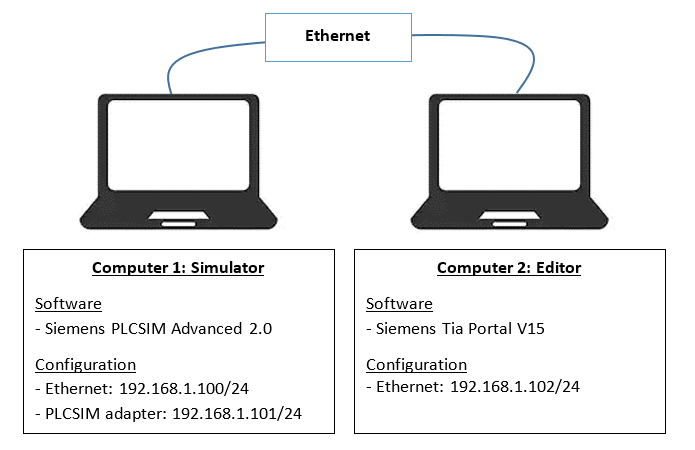

We’ll run the simulator and the editor on two computers :

Simulator configuration

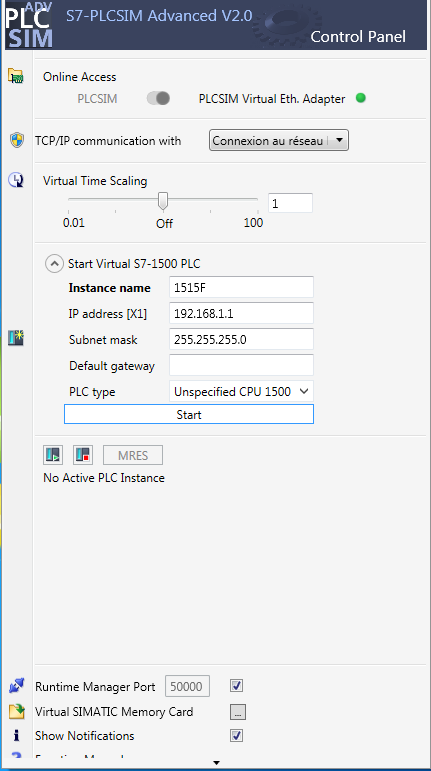

First let’s start an instance with the following parameters :

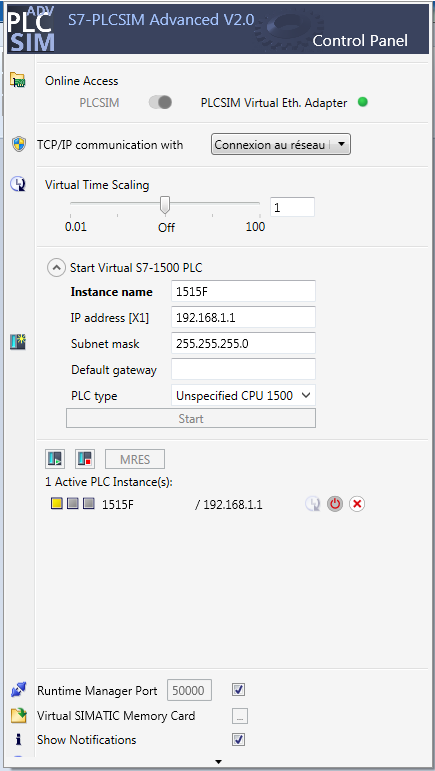

Once started, it should be like that :

PLC Programming

Hardware configuration

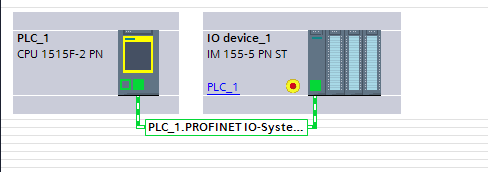

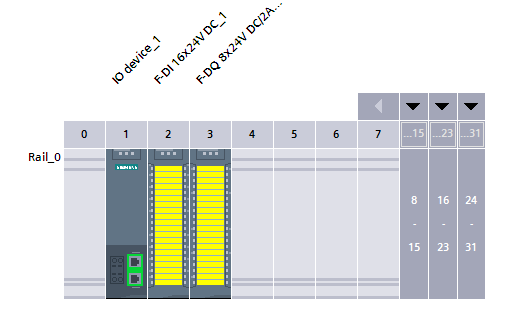

Let’s do a simple configuration as follow :

Network configuration :

– PLC_1 : 192.168.1.1/24

– IO device_1 : 192.168.1.2/24

Note : On the simulator, we have different IP addresses for all the network interfaces : Ethernet adapter, PLCSIM virtual ethernet adapter, PLC and I/Os !

With the following I/Os :

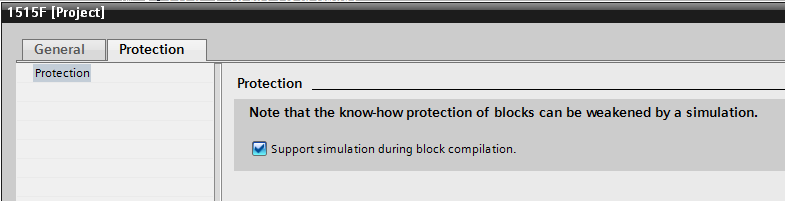

Note that you’ll need to activate this option in the project settings :

Program

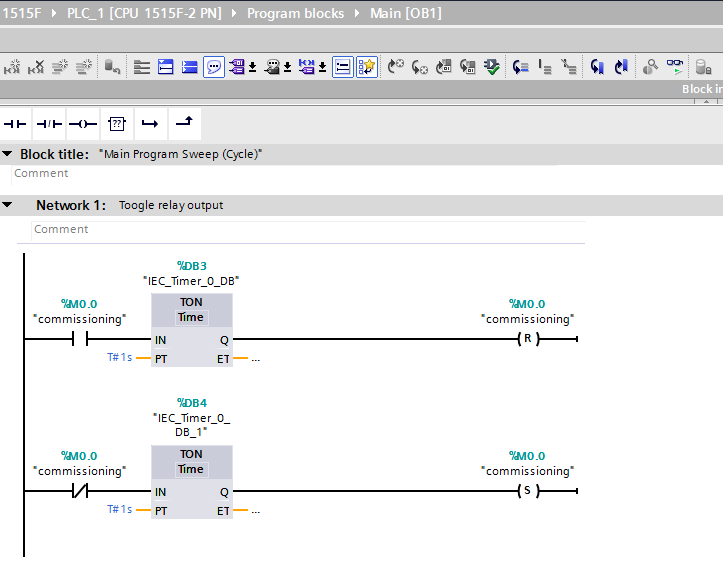

Our program will be very simple ! OB1 will toggle a bit every second :

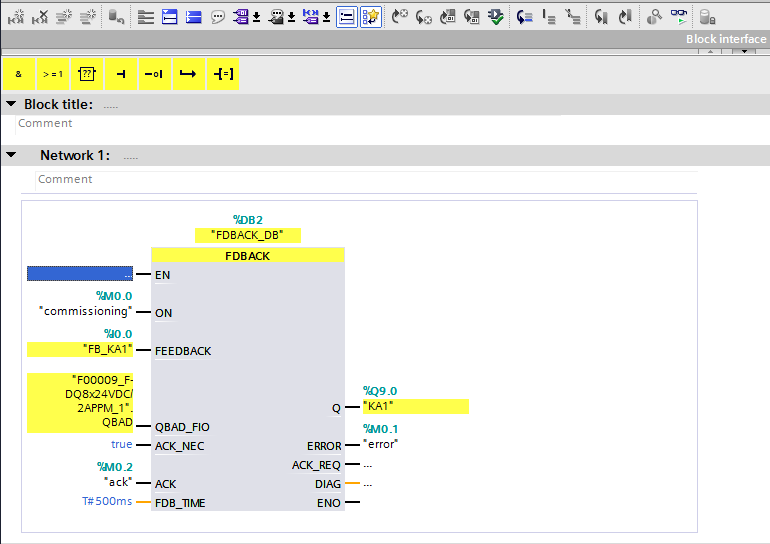

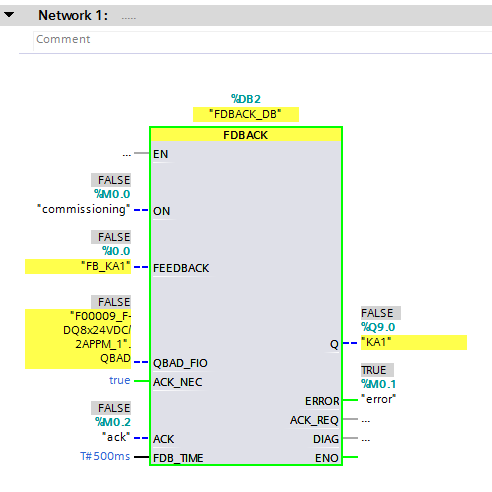

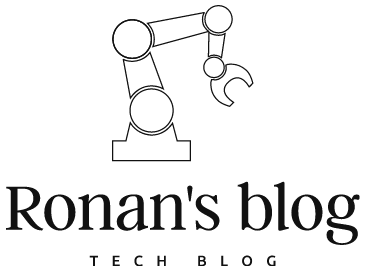

And FB1 will do a safety check between the relay output and the input feedback :

Compiling and loading

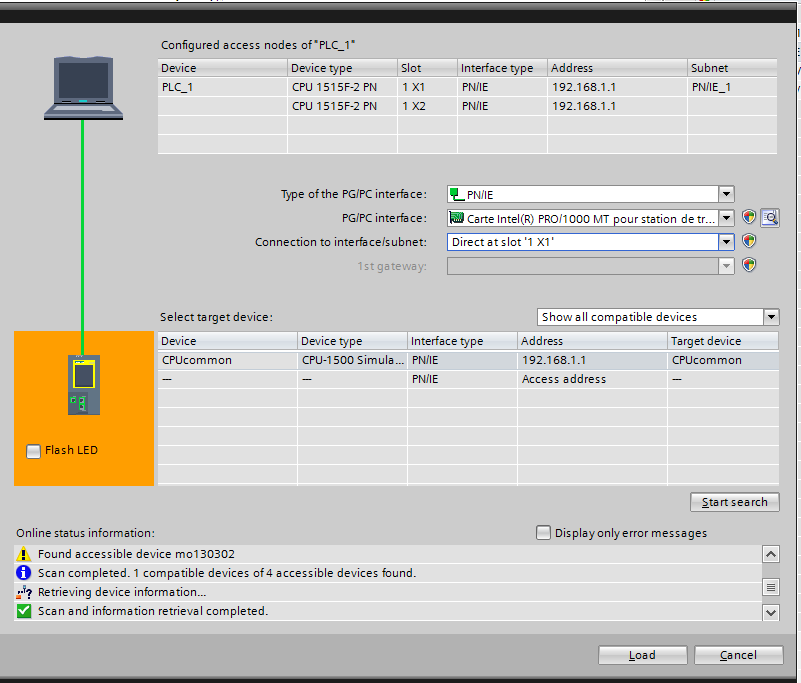

You should be able to compile and load :

Simulation

As soon as you’ll run the program, you should have an error on the feedback monitoring :

Co-simulation

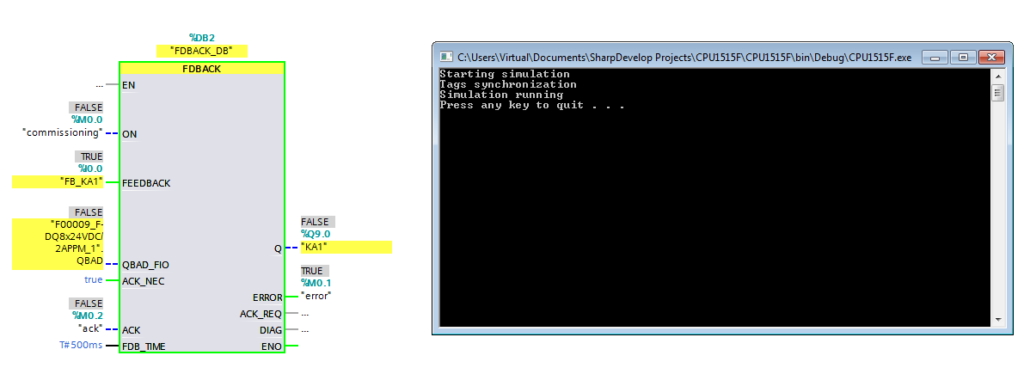

To solve this issue, we’ll running co-simulation with C#. The script will check the output value (%Q9.0) and set the feedback (%I0.0) accordingly. We’ll be using sharpdevelop as IDE.

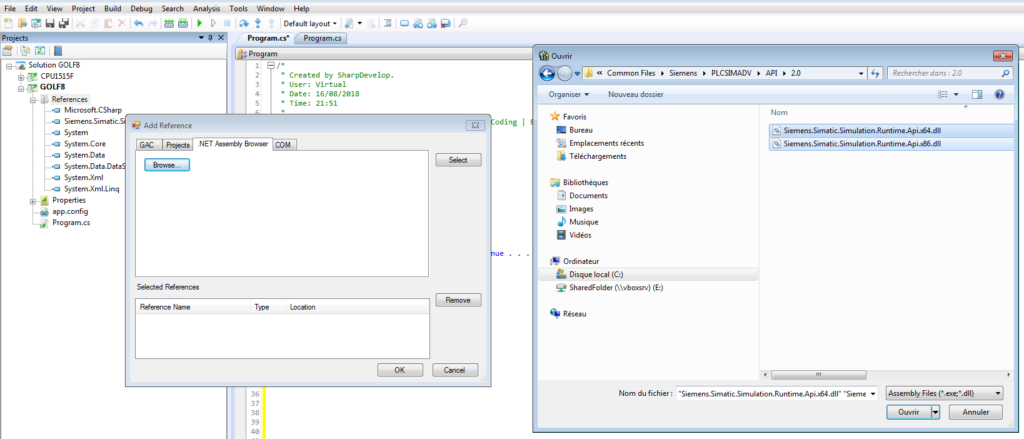

Import DLL

Importing the DLL is easy :

Then we write a short program :

/*

* Created by SharpDevelop.

*/

using System;

using System.Threading;

using Siemens.Simatic.Simulation.Runtime;

namespace CPU1515F

{

class Program

{

public static void Main(string[] args)

{

Console.WriteLine("Starting simulation");

//Use it for local instance

//IInstance myInstance = SimulationRuntimeManager.CreateInterface("Golf8");

//Use it for remote instance

IRemoteRuntimeManager myRemoteInstance = SimulationRuntimeManager.RemoteConnect("192.168.1.101:50000");

IInstance myInstance = myRemoteInstance.CreateInterface("1515F");

//Update tag list from API

Console.WriteLine("Tags synchronization");

myInstance.UpdateTagList();

//Start a thread to synchronize feedbacks inputs

Thread tFeedbacks = new Thread(()=>synchroFeedbacks(myInstance));

tFeedbacks.Start();

//Allow the user to quit simulation

Console.WriteLine("Simulation running");

Console.WriteLine("Press any key to quit . . . ");

Console.ReadKey(true);

}

static void synchroFeedbacks(IInstance myInstance)

{

while(true){

//Keep %I and %Q opposite

myInstance.WriteBool("FB_KA1", !myInstance.ReadBool("KA1"));

}

}

}

}

Code language: C# (cs)And run it :

Once acknowledged, we should not have any issue.

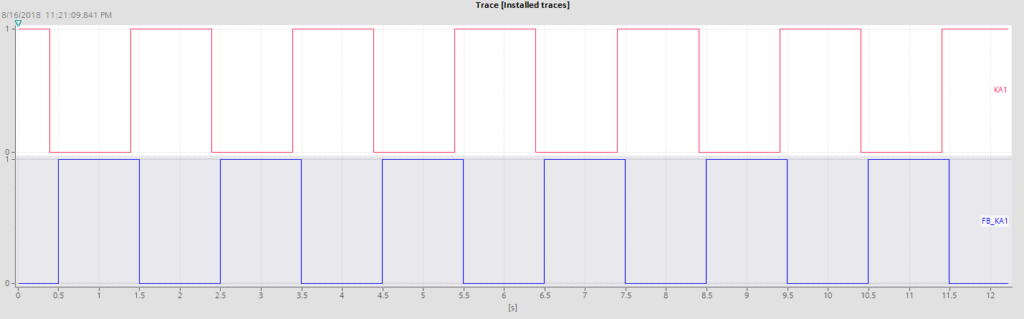

Using the trace tool, we can confirm that it’s running perfectly fine, updating the input in around 100ms.

You’re done with Siemens PLC simulation with virtual commissioning.

Related posts

Interested in home automation, you might be interested in Automation posts or Industrial posts.

Leave a Reply